- TOSIZE.at

- Wood and sheet material

- Veneer

- Veneered MDF

MDF Maple mix veneer

Product information

- Fibreboard with a natural, wooden appearance

- Quiet appearance

- Light colour, easy to lacquer or stain

- Indistinguishable from solid wood when neatly finished with veneer banding

- Easy to work with

- For indoor use only

Description

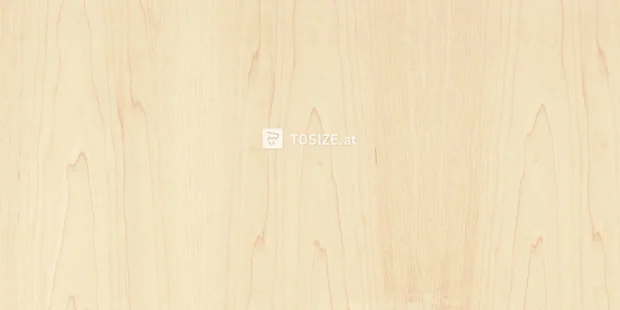

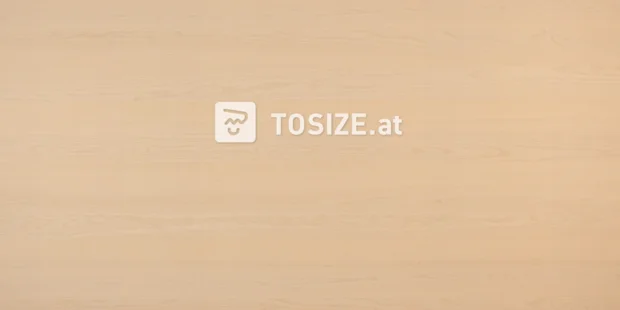

MDF Maple mix veneer is a standard MDF board with a natural appearance, thanks to its top layer of wood veneer. This layer is composed of a combination of crown / plain and kwartiers sawn maple wood, with the wood texture providing a natural-looking panel with a calm appearance. The top layers and end edges have yet to be treated.

Configure MDF Maple mix veneer

How convenient is that

Product information

- Fibreboard with a natural, wooden appearance

- Quiet appearance

- Light colour, easy to lacquer or stain

- Indistinguishable from solid wood when neatly finished with veneer banding

- Easy to work with

- For indoor use only

Description

MDF Maple mix veneer is a standard MDF board with a natural appearance, thanks to its top layer of wood veneer. This layer is composed of a combination of crown / plain and kwartiers sawn maple wood, with the wood texture providing a natural-looking panel with a calm appearance. The top layers and end edges have yet to be treated.

Product properties

Applications

- Furnishings

- Interior

- Cupboards

- Panelling

- Casing

Ordering customised MDF Maple mix veneer boards online

Order cut-to-size MDF Maple mix veneer sheets easily online. Veneered MDF can be sawn to size up to the millimetre. We deliver the panel fully customised to your home. Are you curious about the possibilities? Configure your product, and you will have your project ready in no time.

MDF Maple mix veneer: what is it?

MDF is a popular sheet material that can be used for countless projects. MDF veneered is the standard MDF board with a top layer of crown cut veneered mahogony sheets. The top layer is meant to be kept in sight; the bottom layer is made of technical veneer and is meant to reinforce the board. Because the core of these panels is made of MDF, this panel material is also good and easy to assemble. That is really convenient!

MDF Maple mix veneer, board material with a natural top layer

Unlike melamine faced board material, the top layer of veneered panels is a layer of real wood. This gives the material a calm, natural look. Because it is a natural product, there may be differences in colour and structure between different panels. No two panels are the same. In addition, it is important that this panel is finished with a varnish or oil as desired. This prevents discolouration and preserves the top layer.

The great advantage of veneered board material compared to solid board material is that it does not warp. The MDF core of this board material gives it the advantages of MDF, but the appearance of solid and natural wood.

Maple veneer

Maple-look wood veneer has a bright and light aesthetic, characterised by a soft, neutral colour and a fine, even grain. The veneer often shows subtle markings with a uniform appearance.

The look of maple veneer is fresh and timeless, making it a versatile choice for various interior styles. The colour of the veneer usually ranges from light to medium brown, depending on the specific source of the wood.

Maple wood veneer is often appreciated for its simple and elegant look, making it suitable for furniture, cabinets, interior finishes and decorative elements. Its even grain and bright colour allow maple veneer to be effortlessly combined with other materials and colours, making it a popular choice for both modern and traditional designs.

Crown cut or Quartered veneer

Sawing logs is usually done in two different ways: crown / plain or kwartiers. When the wood is cut crown / plain, long slices are cut lengthwise. This allows the flames of the material to be clearly seen and makes the best use of the wood. In mix, these two techniques are processed interchangeably and used during veneer assembly. This creates a natural whole and each slab is unique.

Available thicknesses of MDF Maple mix veneer

With us, you can order customised, high quality veneered MDF in various thicknesses. You can easily specify the desired thickness in the product configurator. This way, you can be sure that the panel material meets your requirements: both the format and the thickness of the material. The following thicknesses are available: 9 mm, 19 mm and 31 mm.

Machining veneered MDF boards

The board consists of wood fibres that are compressed under high pressure. This makes the material easy to process. When milling or sawing, this board material does not splinter. The fibres are held together by resin. Therefore, it is important to degrease the board properly before varnishing it. Veneered MDF is only suitable for indoor applications and in dry conditions.

Due to sawing, the edges are 'open'. These still need to be finished, which can be done using veneer tape.

Specific applications of veneered MDF

MDF is the material of choice for furniture and interior applications. Veneer MDF, also known as veneer MDF, is a widely usable board that is suitable for various interior applications. A door, a casing for pipes, a bookshelf, a TV cabinet and a partition are just a few examples of the application possibilities of veneered MDF. The homogeneous structure makes MDF, in comparison to other board materials, less susceptible to shrinking and expanding at varying temperatures. MDF veneer is not suitable for applications in damp spaces or outdoors.

Alternatives to MDF Maple mix veneer boards

Is MDF Maple mix veneer not the right timber species for your job? Looking for board material with a different structure? Then go for poplar plywood. Want sheet material that can be used outdoors? Then take a look at phenolic plywood, MDF tricoya or multiplex okoume. Or view our other MDF board materials here: